In Cool Roof France, this idea has made its way. oyster shells recycled are at the heart of the formulation of our products coatings thermo-reflective. Weird ? No ! Why and how has this been made possible ? We will explain everything in this article.

Yes, our mission is to provide solutions that reduce the temperature inside the buildings during periods of high heat. But the goal we have set for ourselves is to carry out this mission in a consistent approach, thus limiting the environmental impact of our products. Then, our teams, R&D have worked, dug, dug to find the materials with the more efficient and less polluting as possible.

The solution ? It was found only a few miles from our office : the oyster shells.

The CaCO3, it speaks to you ? No, it is not to redo a science class of a second. The CaCO3, or more simply calcium carbonate, is an indispensable component in the formulation of our paint-reflective, because it brings him his consistency. And guess what resource contain the shells of oysters… ? It is the calcium carbonate, of course !

These waste thatpiles up in our garbage cans to Christmas are full of potential ! They contain approximately 95 % this valuable mineral. Until then, the calcium carbonate that the industrial sectors used came from quarries, therefore non-renewable sources. Now, it is the result of the powder obtained by grinding the shells of oysters.

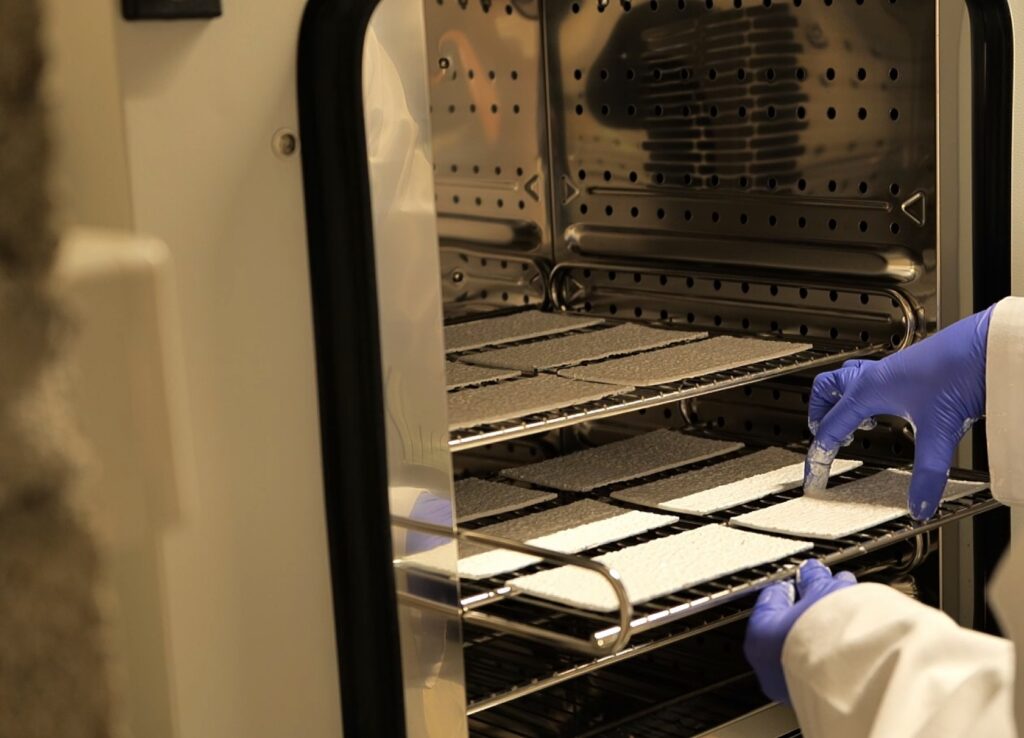

The many technical tests that we have carried out in the laboratory and then on building sites in a large scale, we have to verify the effectiveness of this new formulation écoconçue. But any innovation brings a lot of surprises. Also, in order to ensure that we do not replace’t a problem for another, we checked diligently that this new component generated no other environmental impacts.

To do this, we have made theACV (Life Cycle Analysis*) of our new solution. This has allowed us to characterize our product to more closely ! In fact, theFRENCHAgency for Environment and Energy management, presents the LCA as ” the tool the most successful in terms of overall assessment and multi-criteria environmental impact “. And relief, excitement, victory ! The oyster shell, recycled and then powdered allows pretty to limit the environmental impact of our products thermo-reflective.

“Nothing is lost, nothing is created, everything is transformed. “This quote attributed to Lavoisier, could be the summary of what is the circular economy. The oyster shell, which, until recently, was still to be regarded as waste, is for us today a resource, sustainable, and local more.

For example, they provide the essential nutrients for laying hens, are a amendment mineral sustainable gardening, especially appreciated by the farmer.ice.s biological, and may also be used in the reconstruction of marine ecosystems in the form of natural reefs spat (young oysters).

In Britain, the shellfish industry and the R&D on the revalorization of waste, allow a number of companies to densify the local economy and circular. In the North Finistère, it is the G4DEC, a shared service between the four communities, which leads to the structuring of the sector. In effect, the powder of oyster shells that we use is produced in the West France, from shells collected on the territory. This proximity with our suppliers allows us to limit the distance travelled by the material and therefore, the carbon footprint generated by transport.

If the powder of oyster shells was already used with success in areas of cosmetics, animal feed, or automobile, those in the building and construction had not yet adopted this matter. This has tickled our curiosity and turned out to be a real challenge. We will have not less than two years of development to create our new formulation. Since its establishment, our product has covered more than one million square meters roofs, and each year, enables our customers to optimize their energy consumption, reduce their carbon footprint and improve their CSR.

Today, only Cool Roof proposes a thermo-reflective developed the so… Sassy ? Not determined. And it continues to be !