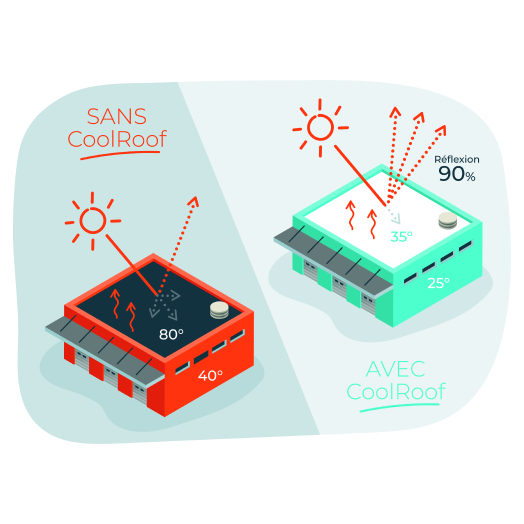

Cool roofing is a technique aimed at reducing the amount of heat absorbed by a building’s roof by using reflective coatings (which reflect a large portion of solar radiation) to cover the roof in white.

This reduces the roof’s surface temperature and significantly limits heat flow into the building.

This technique can be implemented using a variety of materials and can lead to reduced energy consumption for air conditioning and a higher level of thermal comfort.